ORE PROCESSING

Once the ore-bearing rock had been excavated from the mines, it had to be further processed, separating valuable fahlore, chalcopyrite, and other minerals from gangue minerals such as quartz, calcite, or siderite and the host rock (sandstone, shale, etc.). Larger pieces of rock that only consisted of the desired ore mineral were, of course, the main target of mining. As these were, however, a rather rare occurrence, ore concentrate was produced in the mines.

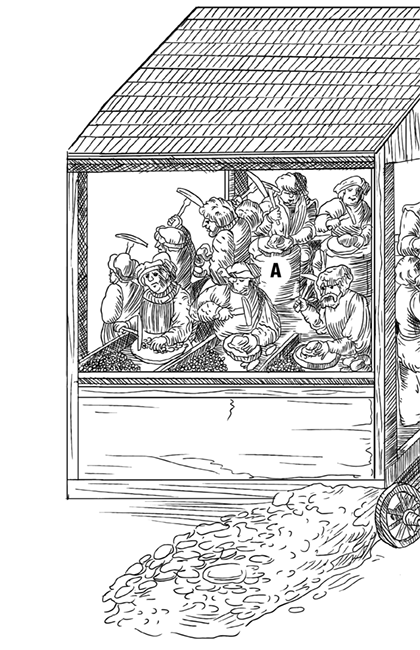

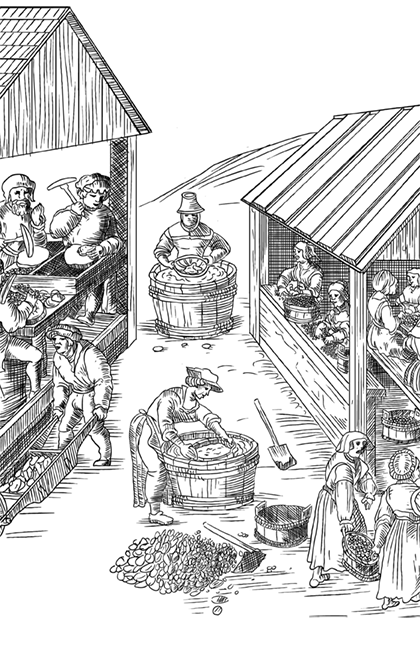

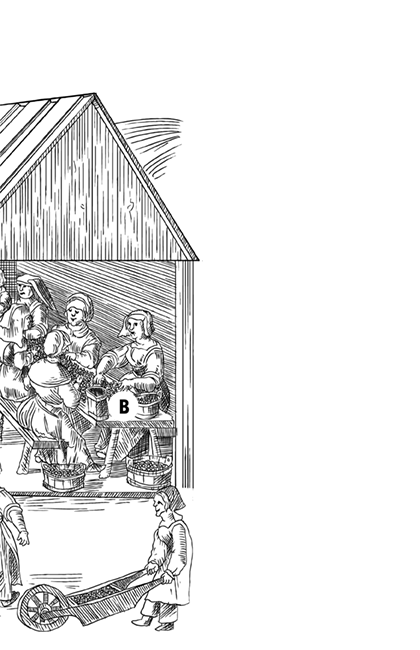

In the first step of mineral processing, called comminution, the rock was crushed on hard, tough stone to separate the ore from larger waste material. Next the ore was sized, which meant it was manually sorted, usually by women. The size of such separation sites and the number of people working there was determined by the richness of the mining site. Larger sites usually had huts that could host more than 10 separators and sorters.

To separate the valuable ore from waste material, a piece of metal was sometimes used to crush the rock on hard, tough gneiss stones. Hornblende gneiss was considered a particularly suitable rock type for crushing the ore. It was also easy to find in the Silvretta crystalline of the Verwall Group south of the Stanzer Valley. Once the ore mineral pieces were reduced to a size where sizing by hand was no longer possible, they were set aside for the next step, for concentration.

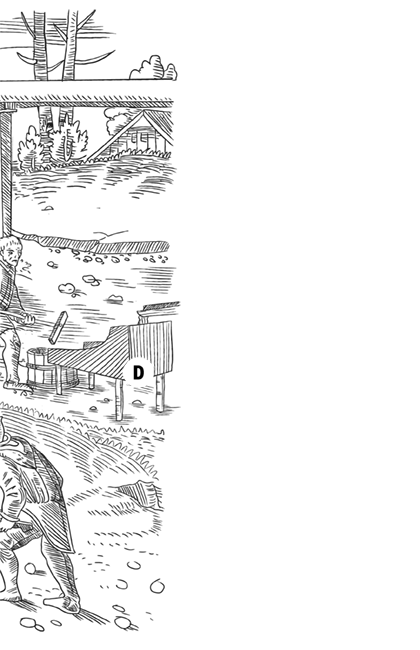

The first water-powered crushing devices used for comminution of the separated ore to obtain fine particles stem from the 16th century. These mechanical mill machines were generally referred to as stamp mills. Once the ore was small enough, it was moved to a slightly slanted table specifically designed for ore concentration, i.e. separating as much of the gangue from the metal by moving it with a sort of cam through running water, thereby washing it.

This was usually women’s work. The ore that was separated in this way was usually considered of poor quality and therefore less valuable. As various sources suggest, plans were made by Gand miners to build a stamp mill near the Lengerui River in 1575. Yet, the project was not carried out before the local mines were closed. An authentic, and working crushing device of this type can be visited in the nearby Knappenwelt Gurgltal in Tarrenz.

Fig.: Particularly small stone used for crushing in the Ringenwechsel mine close to Schwaz, considering that such stones often had over 100 kg